Recently, we’ve seen and heard a number of folks claim that shipping Passivhaus windows from Europe isn’t the ‘sustainable’ solution – but we’ve never seen any data to really back that up. People seem to assume that local always equals more sustainable. But is this necessarily the case?  We weren’t so sure, especially after crunching the numbers through PHPP on a potential Passivhaus in the Northwest. Our realization during this task was that certain European windows allowed us to achieve Passivhaus with significantly less insulation than any North American window could. This really didn’t seem that odd to us, as high performance windows being developed in Europe are pretty superior to here in North America, and the quality of glazing overseas is fairly stunning as well – high solar heat gain coefficients (SHGCs), low U-values and superior visible transmittance (VT). What follows are some quick, back of the napkin calculations that make the argument that shipping high performance windows from Europe might actually save CO2. A lot of CO2.

We weren’t so sure, especially after crunching the numbers through PHPP on a potential Passivhaus in the Northwest. Our realization during this task was that certain European windows allowed us to achieve Passivhaus with significantly less insulation than any North American window could. This really didn’t seem that odd to us, as high performance windows being developed in Europe are pretty superior to here in North America, and the quality of glazing overseas is fairly stunning as well – high solar heat gain coefficients (SHGCs), low U-values and superior visible transmittance (VT). What follows are some quick, back of the napkin calculations that make the argument that shipping high performance windows from Europe might actually save CO2. A lot of CO2.

In addition to the baseline model with European windows and glass, we ran three North American windows with high SHGC triple pane glazing through PHPP and then adjusted the amount of insulation needed to achieve the Passivhaus standard. We’ve taken the approach that the client wouldn’t want anything to change. Therefore, window size and orientation, building assemblies, etc. remain as intended, and we’re merely adding EPS insulation as needed.

First, we need to determine a few things…

Shipping weight of windows

448 sf x 6.13 lbs/sf = 2746.24 lbs (1.25 tons)

Envelope areas

Wall area = 3,302 sf

Slab area = 1,360 sf

Roof area = 1,360 sf

EPS foam CO2 (4’x8’x1” EPS type IX insulfoam)

5.33 lbs x 5.5 lbs CO2/lb= 29.3 lbs CO2 per sheet

Freight CO2 rates

Sea = 0.0887 lbs CO2 per ton-mile

Truck = 0.3725 lbs CO2 per ton-mile

Baseline Model w/ European window

Our baseline is the as-designed building.

Window: Internorm Varion

Glazing: Glastroesch (0.64 SHGC, 0.105 U-value, 0.73 VT)

Specific space heat demand: 4.74kBTU/ft²a

EPS insulation at envelope assemblies

3” EPS at wall

4” EPS at roof

6” EPS at slab

Baseline Shipping CO2

Trucked from factory in Lannach (AT) to Rotterdam (700 miles), shipped from Rotterdam to Portland (8,685 nautical miles/9,988 miles)

700 miles * 0.3725 * 1.25 tons = 326 lbs CO2

9,988 *1.25*0.0887 = 1,107.5 lbs CO2

Total Baseline CO2 = 1,433.5 lbs

Option A: Serious Windows

Window: Serious Window 925 series

Glazing: Serious 9 (0.47 SHGC, 0.107 U-value, 0.45 VT)

Specific space heat demand: 6.68kBTU/ft²a.

In order to achieve the standard (ultimately coming in at 4.68kBTU/ft²a), more insulation is needed.

EPS insulation at envelope assemblies

Add 2” EPS to wall = 6,048 lbs CO2

Add 2” EPS to roof = 2,490 lbsCO2

Add 5” EPS to slab = 6,225 lbsCO2

Serious Windows Shipping CO2

Trucked from factory in Longmont, Colorado (1,285 miles)

0.3725 *1,285 miles * 1.25 tons = 561.5 lbs CO2

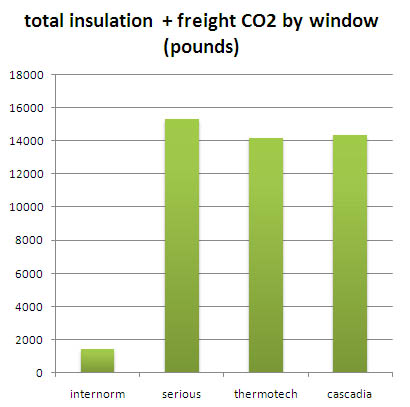

Total Serious Windows CO2 = 15,324.5 lbs

Option B: Thermotech Windows

Window: Thermotech fiberglass

Glazing: 322 Gain #3#5 (0.61 SHGC, 0.16 U-value, 0.63 VT)

Specific space heat demand: 6.22kBTU/ft²a.

In order to achieve the standard (ultimately coming in at 4.72kBTU/ft²a), more insulation is needed.

EPS insulation at envelope assemblies

Add 1” EPS to wall = 3,024 lbs CO2

Add 4” EPS to roof = 4,980 lbs CO2

Add 4” EPS to slab = 4,980 lbs CO2

Thermotech Windows Shipping CO2

Thermotech windows are manufactured in beautiful Ottawa, Ontario (2,642 miles)

0.3725 *2,642 miles * 1.25 tons = 1,230 lbs CO2

Total Thermotech Windows CO2= 14,214 lbs

Lastly, the local option – it’s always greener to go local, right? Let’s take a look…

Option C: Cascadia Windows

Window: Cascadia fiberglass frame

Glazing: Cardinal 179 LoE#2#5 (.57 SHGC, 0.17 U-value, 0.69 VT)

Specific space heat demand: 6.78kBTU/ft²a.

In order to achieve the standard (ultimately coming in at 4.71kBTU/ft²a), more insulation is needed.

EPS insulation at envelope assemblies

Add 2” EPS to wall = 3,024 lbs CO2

Add 4” EPS to roof = 4,980 lbs CO2

Add 5” EPS to slab = 6,225 lbs CO2

Cascadia Windows Shipping CO2

Cascadia windows are manufactured just across the border in Langley, BC (294 miles)

0.3725 *294 miles * 1.25 tons = 137 lbs CO2

Total Cascadia Windows CO2 = 14,366 lbs

This was shocking to us, as we expected the numbers to be significantly closer. Of course, the locally manufactured windows had the lowest transportation CO2 production – that only makes sense. However, the superior frames and glazing from Europe require significantly less insulation in the envelope. This definitely seems backwards and goes against conventional wisdom, but in this instance, shipping windows from Europe saves CO2 – a whole lot of CO2. In fact, with an average of 14,634 lbs CO2 for the three North American options, the European windows can save six tons of CO2 emissions. That is not insignificant, and something to keep in mind if North American manufacturers don’t think that developing high performance glazing is a worthwhile venture.

This was shocking to us, as we expected the numbers to be significantly closer. Of course, the locally manufactured windows had the lowest transportation CO2 production – that only makes sense. However, the superior frames and glazing from Europe require significantly less insulation in the envelope. This definitely seems backwards and goes against conventional wisdom, but in this instance, shipping windows from Europe saves CO2 – a whole lot of CO2. In fact, with an average of 14,634 lbs CO2 for the three North American options, the European windows can save six tons of CO2 emissions. That is not insignificant, and something to keep in mind if North American manufacturers don’t think that developing high performance glazing is a worthwhile venture.

We realize that a more sustainable wall assembly would probably be utilized in most situations, rather than stacking on more EPS, but we wanted an apples to apples comparison between the windows from a performance standpoint. Regardless, the North American windows would all require several inches of EPS in the slab. Production of just one inch of EPS in the slab emits 1,245 lbs of CO2, which is almost equal to the CO2 emissions of importing the European windows. Additionally, the Internorm window is a clad wood window, which as architects we’re more drawn to versus fiberglass. I’m not aware of any wood window produced locally that comes close to Passivhaus standards. And here in the gray and gloomy winters of the Northwest, windows with a higher VT, such as the Glastroesch, are definitely a great bonus.

We’re definitely interested in any thoughts/critiques readers may have on this one.

Great work, this is why this blog is a fantastic resource. Can you talk a little about where you got the base information such as freight C02 rates and EPS foam C02 amounts?

Thanks, Tim. Far from scientific, but this clearly works in the Northwest. I’m not sure how this would pan out in Minnesota or New England.

CO2 freight emissions were from the carbonfund, which are derived from a German site.

EPS foam has a density of 2 pcf, so total weight is 2(4’*8’*0.083) =5.33 lbs.

According to Alex Wilson’s “Avoiding the Global Warming Impact of Insulation” article, the CO2 of EPS is 2.5kgCO2/kg or 5.5lbs CO2/lb

5.5 lbs CO2 * 5.33 lbs = 29.3 lbs CO2 per 4’x8’x1″ sheet of type IX insulfoam

Thanks for this great resource, dispelling the notion that local is inherently superior (take that LEED).

As architects, we need to be prepared to make evidence-based decisions, and to elucidate the fact that smart ecological / environmental decisions translate into smart economic decisions. Carbon footprint is a fine metric to base a decision upon, but lets face the reality that most Americans understand decisions in terms of cost, not carbon.

More to the point, how do these scenarios pencil out financially?

That’s a good question, and we really haven’t had a chance to address that yet as we’re still waiting on information from Internorm. Additionally, it’s difficult to obtain an accurate comparison because the Internorm window is a clad wood window (and price fluctuates daily with exchange rate), and the other three are all fiberglass. But if you compare the price of the Internorm (or Optiwin) to decent wood windows manufactured in North America, they’re pretty close. So if we’re looking at a similar product, with a superior performance that means less CO2 emissions even if shipped from Europe, that’s a no-brainer.

We can calculate the cost implications of additional EPS (not including additional materials and labor) – and if I recall correctly, type IX costs about $11.25/4’x8′ board.

Baseline w/ Internorm windows:

0 add’l EPS boards * $11.25 = $0

Option A Serious windows:

507 add’l EPS boards * $11.25 = $5,703.75

Option B Thermotech windows:

447 add’l EPS boards * $11.25 = $5,028.75

Option C Cascadia windows:

593 add’l EPS boards * $11.25 = $6,671.25

On average, the North American windows require $5,800 sf additional insulation, which probably comes close to shipping costs from Austria if the shipment can be split with another local customer – and still saves six tons of CO2 emissions.

While the Optiwin windows you have pictured may be the ultimate “green” and energy performer window product, we could do far better. For instance, Sweden’s home building industry has many window products that offer 80-90% of the performance of the Optiwin units, using a relatively straightforward aluminum clad wood window unit – it may not contain magic cork, or wool shorn from sustainable sheep, but its something that our in-place industry could easily produce here right now, and produce at a price that could be widely adopted. In the end the country would benefit most from 90% of houses incorporating 75% of the Optiwin’s performance, instead of 5% of houses getting 100% of Optiwin’s benefit.

Greg,

I wouldn’t say Optiwin’s the ‘ultimate energy performing window’, though there are few frames that perform as well. Internorm’s Varion is a clad wood window (sans cork), and could easily be manufactured this side of the pond.

For this project, it really came down to the glazing – and there just isn’t a triple pane unit manufactured in North America that we’ve found with as high an SHGC combined with low U-value and a really decent VT.

I agree that much of the country would benefit from windows that performed 75% as well as Optiwin or Internorm (or Thermotech) – but until codes require significantly better performing products and congress stops rewarding sub-par performance with credits (such as the ridiculous ARRA 30/30) I don’t think we’ll see the demand that pushes manufacturers to make better products.

I’d like to know more about how you modelled our windows, for example;

What did you use for Uframe and psi?

Did you use any fixed windows?

– if so what numbers did you use for them?

thx

Stephen Thwaites

Thermotech Fiberglass Fenestration

Stephen,

all windows modelled as casement.

Thermotech:

Uframe = 0.19

Psi = 0.020 (assumed warm edge spacer in every case)

If you have better numbers for PHPP inputs, I’ll gladly rerun.

Hi, I’m not in the window or construction business, just a curious and ever-learning passerby. This is fascinating, puzzling, … and a bit disturbing.

Perhaps someone would be willing to take the time to educate me a bit and explain or share an opinion as to WHY U.S. manufacturers, especially MN window makers, don’t make windows with these higher performance abilities?

Surely Sweden and MN have similar needs? Why aren’t MN makers matching – or surpassing- European and Sweden’s window makers?

Is there a reason why we’re not utilizing these glazing techniques?

Is it cost? Exclusive patents? Or are we so behind in R&D? A lack of consumer demand? Something else?

Puzzled and curious,

Jill

For the glass option you listed i would use

for casement/ awning windows

Glass; G=0.61 , U=0.16

Frame; H=2.7″, U=0.26, psi=0.0

(Uframe includes effect of psi)

for fixed windows

Glass; G=0.61 , U=0.16

Frame; H=1.9″, U=0.26, psi=0.0

(Uframe includes effect of psi)

For south facing windows you might want to consider switching the clear lite for low iron which boosts the G to 0.63

Using the fixed window helps our numbers because the fixed frame is about half the height of Euro PH frames, so the solar gain is greater than for Euro PH frames

Stephen,

That drops specific heat demand down to 6.02kBTU/ft²a from 6.22. I’ll revise numbers when I get a chance – probably after PH exam Wednesday. Will show thermotech as lowest CO2 amongst the three N.A. windows.

What is the U-value on the low-iron glass with g-wert=0.63?

We’re definitely aware of the performance of the thermotech fixed windows.

And the reduced spacer psi definitely makes a difference. Thanks.

Jill:

Europeans calculate U differently than North Americans. Perhaps not surprisingly to snowbelters like myself, they use a smaller indoor-outdoor temperature difference – a reflection of their warmer climate.

This smaller temperature difference leads them to having bigger spaces (3/4″ instead of 1/2″) between the glass panes. This is an advantage in the PH world which uses European standards. In the PH world they can claim lower U’s than if they followed North American (NFRC) procedures.

low iron glass doesn’t change U

I suspect the Glastroesch glass you are evaluating is their ‘Sanco Silverstar TrIII E Solar”

Is this the one?

If so, did you notice all 3 lites are low iron and they are using a Krypton fill?

If that is the base case, perhaps you should compare our Kr filled casement which would have a European glass U of 0.128 .

thx

ST

that is the one.

thermotech has an R-44 glass?!?

Yikes!, i should’ve been clearer

When using Euro procedure for calculating Uglass we get 0.128 in imperial units (0.73 in metric) when filling 322Gain w/ 90% krypton

Hope that’s more clear, sorry for the lack of precision

ST

Interesting analysis, but I am curious why you chose to use EPS for the added insulation. If you substituted Polyiso in this analysis instead of EPS would the carbon savings not be substantially lower?

Scott,

Adding thicker walls with cellulose would be far more savings in CO2, but we were looking at utilizing EPS for slab and roof (green roof), and so for ease of calculations, used EPS on the walls to keep it simple.

Per Alex Wilson, polyiso’s embodied CO2 is about 6.6 lbs CO2/lb.

Polyiso comes in varying densities, if we take a lighter one, 1.65 pcf, total weight is 1.65(4′*8′*0.083) =4.4 lbs.

One 4′x8′x1″ sheet of low-density polyiso= 4.4 lbs x 6.6 lbs CO2/lb = 29 lbs CO2. We’d need a 3/4″ sheet of polyiso to equal 1″ of type IX insulfoam.

The same amount of additional EPS in slab and roof would have to be used, but there would be a slight CO2 reduction in the walls.

1″ of EPS in the walls emits 3,024 lbs CO2

3/4″ polyiso emits 2,262 lbs CO2.

In these options, we would see either a 750 lbs or 1,500 lbs CO2 savings from usage of polyiso instead of EPS. I don’t know that we would consider that substantial.